Extrusion

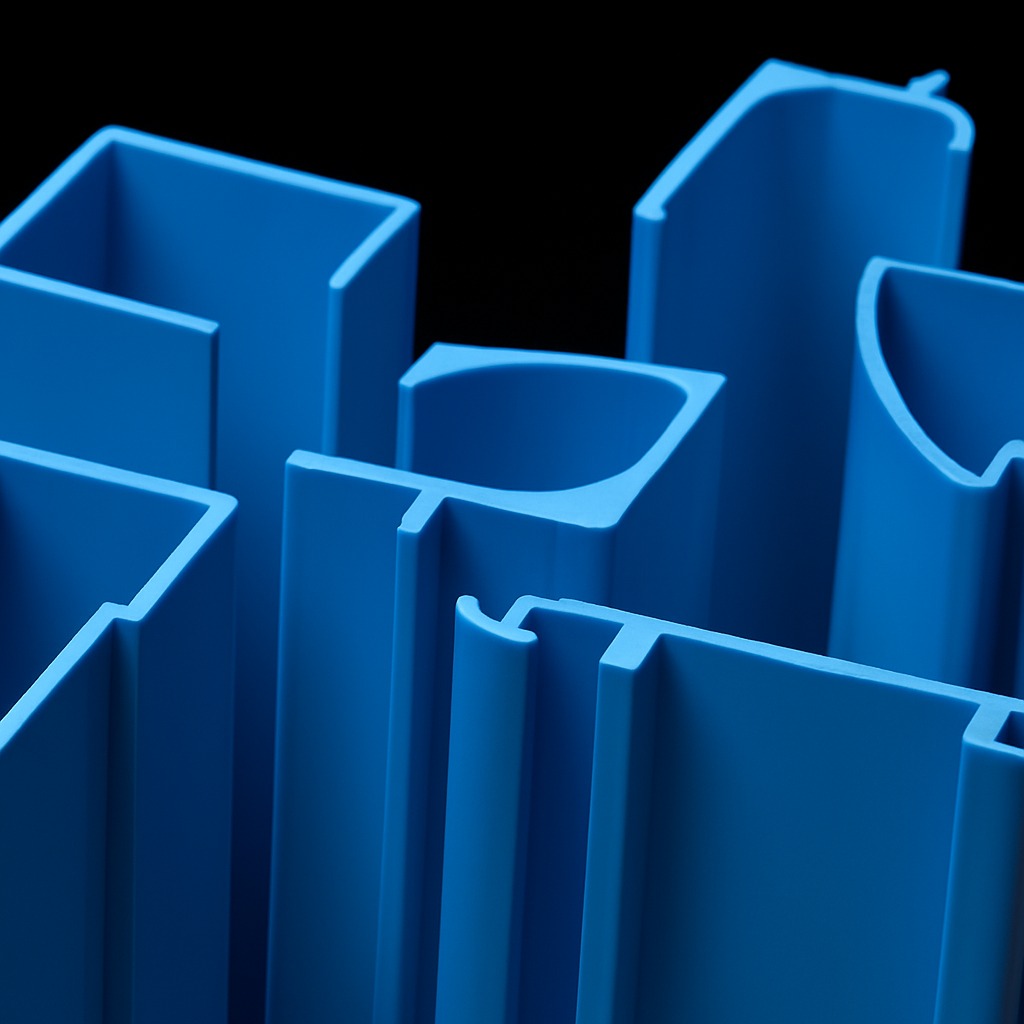

At STS Brothers, we specialize in precision plastic extrusion, delivering custom parts and components for a variety of industries.

What Is Plastic Extrusion?

Plastic extrusion is a continuous process where raw plastic is melted and pushed through a custom die to form a consistent cross-sectional shape. It’s ideal for making long and uniform products like pipes, tubes, window frames, and plastic profiles—widely used in construction, packaging, and automotive industries. The process offers high efficiency, low material waste, and excellent dimensional accuracy. With various resins available, it allows flexibility in color, texture, durability, and strength. Co-extrusion and post-processing options like cutting, embossing, or printing add further customization, making it a reliable, scalable, and cost-effective manufacturing method.

Its ability to run continuously ensures faster turnaround times and consistent product quality. This makes plastic extrusion a preferred choice for high-volume production across diverse market needs.

The Benefits of Plastic Extrusion

Continuous Production

Extrusion is ideal for producing high volumes of parts with uniform cross-sectional profiles. Its continuous process enables fast production, reduces downtime, and ensures on-time delivery.

Material Efficiency

Plastic extrusion offers a cost-effective solution, especially for high-volume production, thanks to its efficient process and optimized material usage.

Versatility

Plastic extrusion supports a wide range of materials and designs, from flexible tubing to rigid profiles, making it a versatile solution for various application needs.

Customizable

With diverse material options and custom die capabilities, extrusion offers the flexibility to design and produce products tailored precisely to your specifications.

Our Extrusion Process

Material Preparation

At STS Brothers, we begin by selecting the right raw plastic materials for your project, based on the required properties and specific application needs.

Melting & Extrusion

The raw plastic is melted and extruded through a custom-designed die to create the exact cross-sectional shape required for your product.

Cooling

The extruded plastic is evenly cooled to preserve its shape and structural integrity throughout the process.

Cutting & Part Removal

After extrusion, the continuous product is precisely cut to the required length, ready for use or further processing.

Quality Inspection

We perform rigorous quality checks on all extruded products to ensure they meet exact design specifications and performance standards.

Packaging & Shipping

Finally, the finished products are carefully packaged and promptly shipped to ensure they arrive on time and in perfect condition.

Excellence in Pakistan-Made Plastic Extrusion

At STS Brothers, our dedication to quality, precision, and customer satisfaction sets us apart in the plastic manufacturing industry. Partner with us to bring your next project to life with the reliability and efficiency of a trusted local expert.

Sustainable Manufacturing Innovation

We’re committed to sustainability by incorporating eco-friendly materials like bio-based and recycled plastics into our manufacturing process, delivering high-quality products that support a cleaner, greener planet.

Why Choose STS Brothers?

Direct Communication

Experience seamless collaboration with STS Brothers. We ensure open and direct communication every step of the manufacturing process.

On-Site Manufacturing

All production is done in-house at our facility, allowing us to maintain strict quality control and consistently deliver products that meet our highest standards.

No Outsourcing

Your projects are handled entirely by our skilled team at STS Brothers. We never outsource, ensuring every part is crafted with precision right here in Pakistan.

Fast Delivery

Our streamlined processes and in-house manufacturing allow us to deliver quickly, minimize lead times, and keep your projects right on track.

Our clients

What to Expect After You Send Your Message

- Our team will go over the details you provided.

- One of our team members will reach out to you shortly.

- We'll prepare a detailed quote based on your needs.